Class: Intro to Wearables (Jingwen Zhu, Spring 2019)

Assignment: Create a soft circuit using 1 battery, at least 2 LEDs, and 1 switch; be creative with the switch.

For our first assignment, we were given the chance to create any soft circuit we wanted, on whatever we wanted––existing clothing or not. When thinking about creative ways of making a switch. I knew I wanted to take inspiration from the affordances of existing clothing and I found it in my dear friend and roommate Paul.

Paul is a dapper gent. He wears hats and ties and jackets daily. Occasionally, when the stars align and we go out for a particularly campy good time, he will don a pair of disco shoes with flashing multicolor LEDs in the soles.

When I was talking to him about this class, he suggested I make him a tie to go along with those shoes. He even went so far as to donate an old tie he didn’t mind being destroyed to the cause.

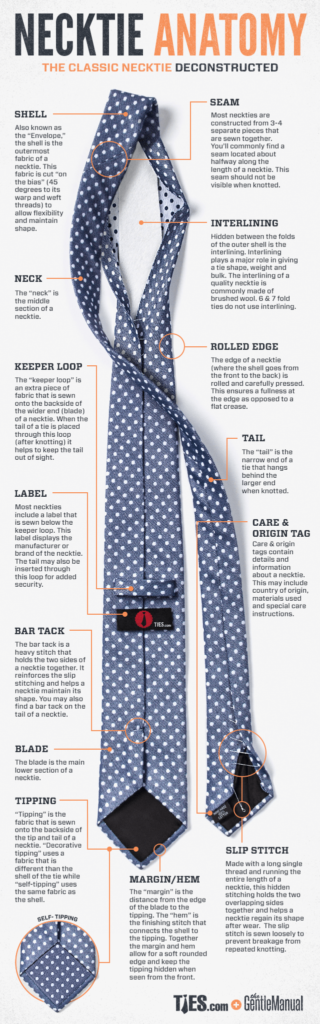

I started by looking at a tie’s design and considered what affordances for human/tie interaction there are. A tie is tied around the neck with varying types of knots. There is always a little strap (keeper loop) on the back to tuck the tail end of the tie so that it doesn’t flap around messily. It also often utilizes a tie clip to keep in place against a buttoned down shirt. A lot could be made of any of these affordances when designing a soft circuit through a tie.

I decided that the act of tucking the tail end of the tie into the keeper loop would be the action that completes the circuit in order to turn on the embedded LEDs. A coin cell 3V battery would be sewn into the loop itself and the loop tightened in order to make a solid connection.

Then, I began thinking about what kind of LEDs to use and where to put them. Luckily the shop had some blue LEDs available that were more delicate than the standards.

Based on the diagonal, blue striped pattern of the tie, I decided I would sew three of them along one of the stripes toward the bottom. I thought it would look more interesting than just having one or two right in the middle. Then I got to it and immediately forgot everything I learned last year about circuits.

First, I had Paul tie the tie so I could pin where the end of the tie fell based on his anatomy.

The red pin marked where the tail end of the tie fell on the feeder loop and the yellow pin marked where Paul would place the tie pin.

Then I sewed the LEDs into the pattern:

The ground of the LEDs would sneak around the back of the tie and end under the fedder loop:

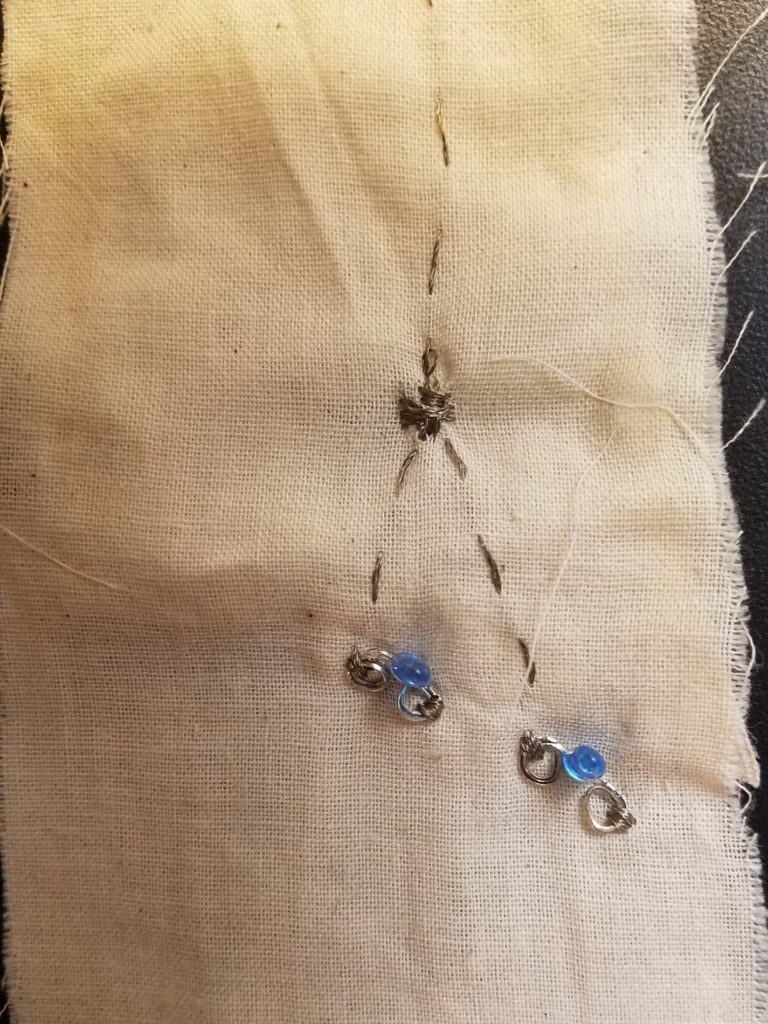

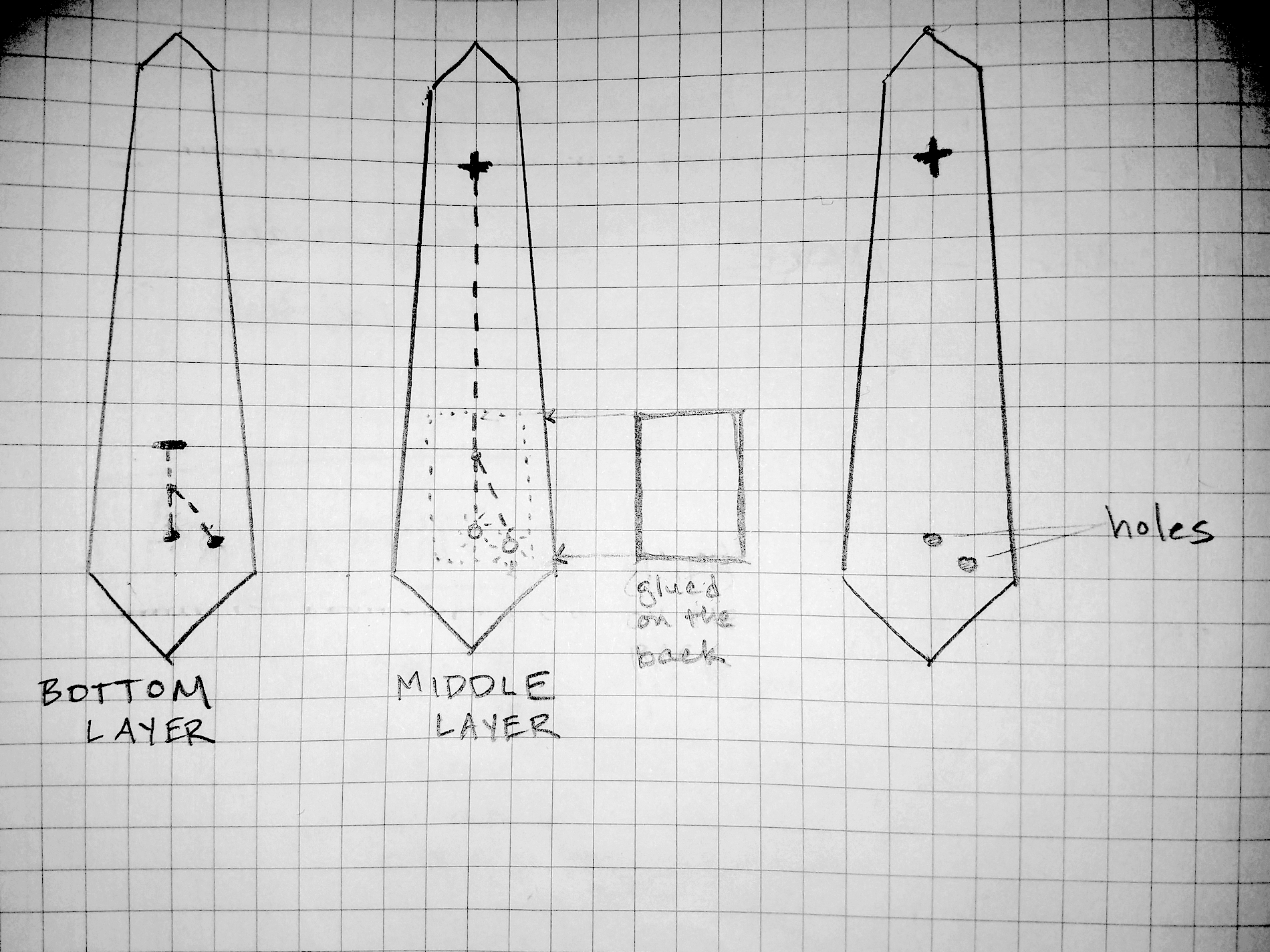

Unfortunately, I completely forgot that you cannot just put multiple LEDs together in sequence. I had to completely undo everything and rethink the logic of my circuit in order to make the LEDs wired to the battery in parallel. I figured I could get away with 3 LEDs before the brightness dimmed too much:

On the right I drew out the simplest way to sew the circuit.

I starting sewing again but quickly realized that I would have to deconstruct the entire tie to make it work. Ties are tied, you see, and if I were to sew directly into the outside shell, the circuit would surely short as soon as the conductive thread was tied together with the fabric. Not wanting to go completely down this road, I decided to prototype the idea (like I should have done from the start).

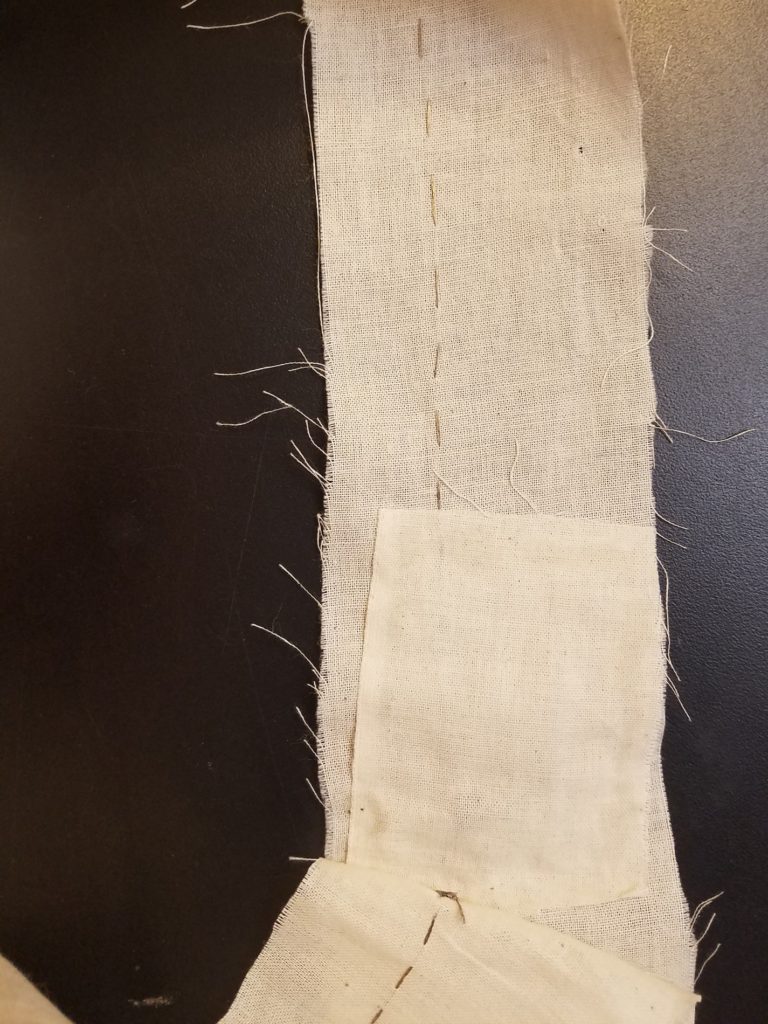

Luckily there was some spare muslin in the soft lab. I quickly realized that I would have to spread my circuit over three different layers of fabric to prevent shorting, even added a strip of glued on fabric to the middle layer to prevent the ground from touching the power side. I of course forgot to take pics while I was doing it so here’s a rough diagram of each of the layers:

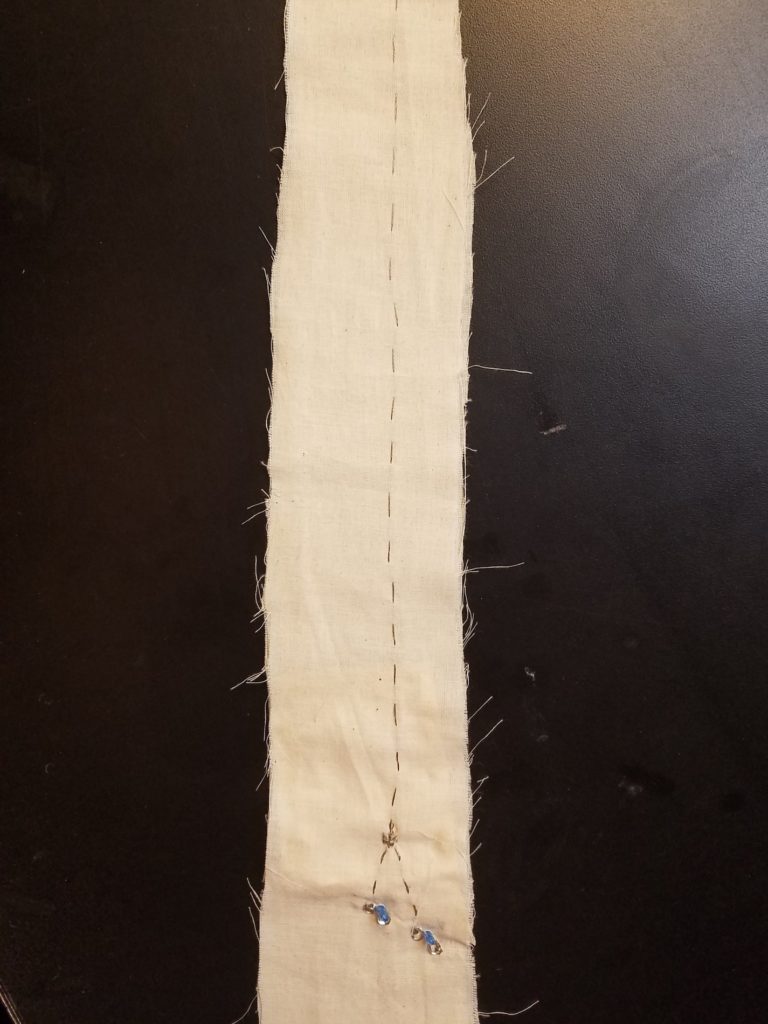

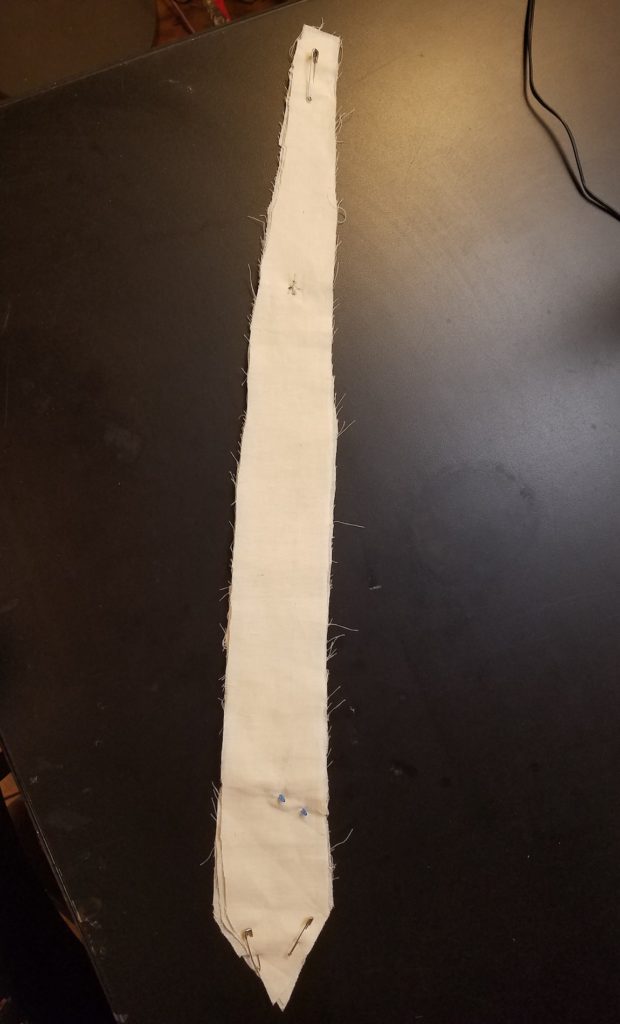

Here is an overview of the finished, working prototype:

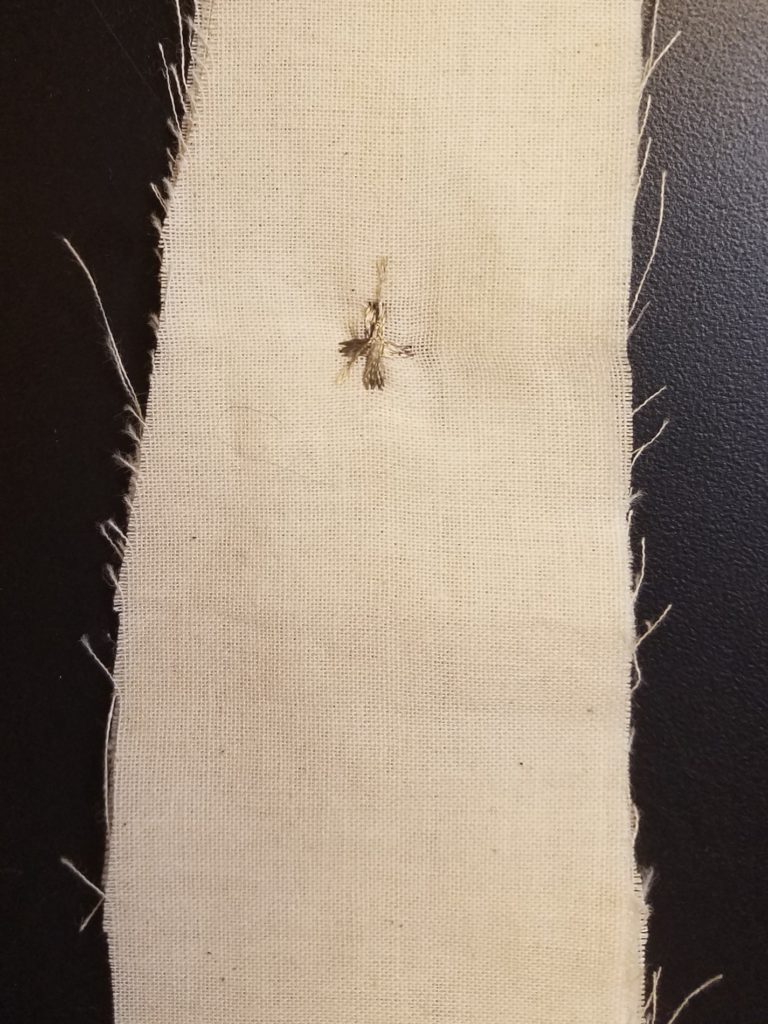

Bottom layer: cathodes sewn to ground.

Middle layer, back view: fabric glued to prevent contact with the bottom layer

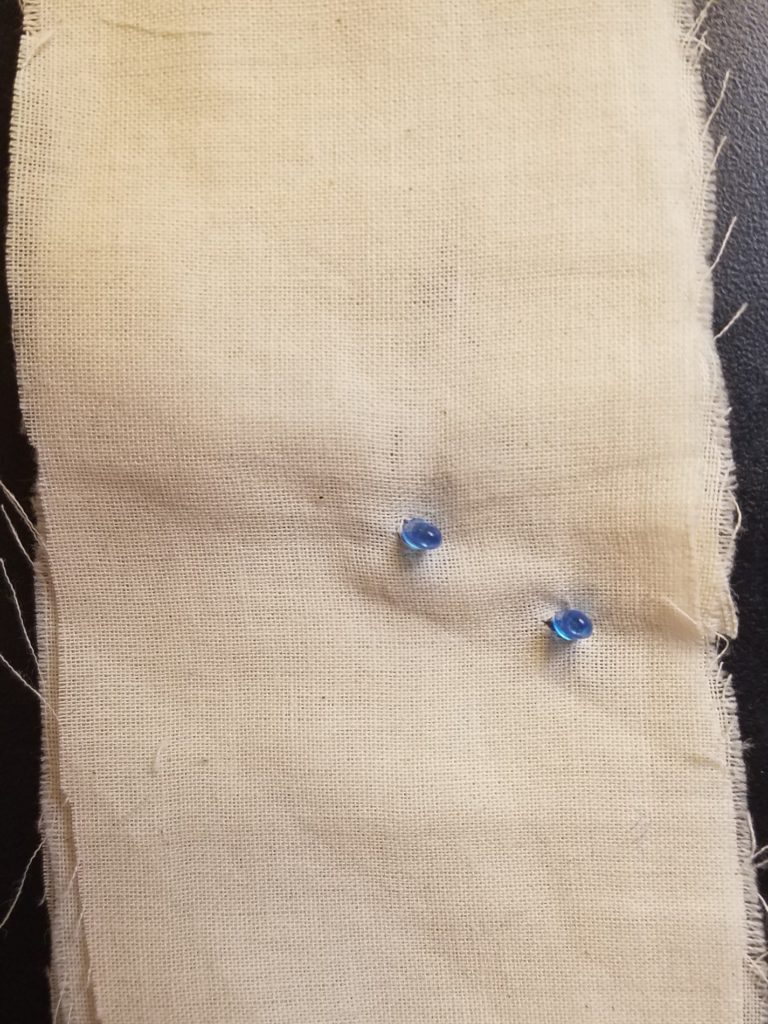

Middle layer, close up of LEDs

Middle layer, full view

Top layer, close up of LEDs poking thru holes

Top layer, close up of power connection

Finished prototype

My next step will be to transfer this to fabric that can be inserted as lining into a finished tie.

Leave a Reply

You must be logged in to post a comment.